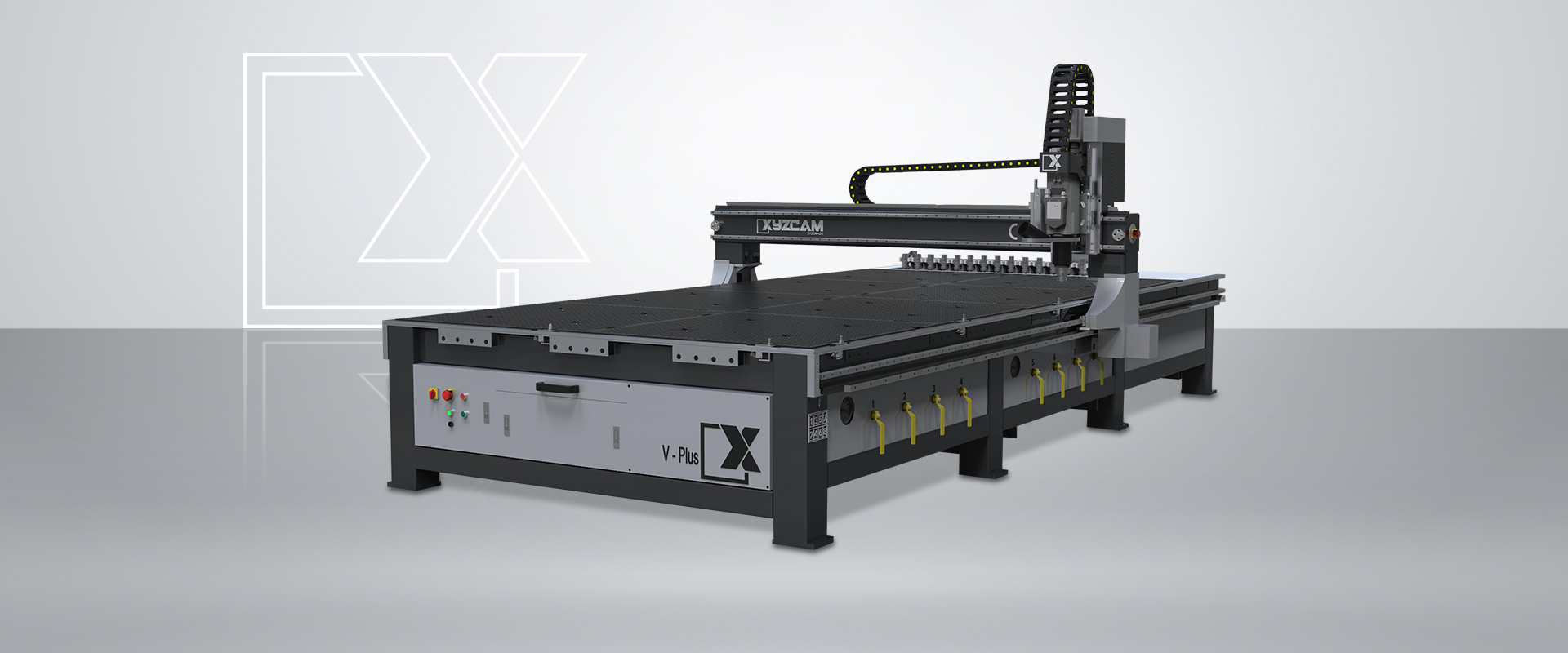

Die Leistungsstärkste Portalfräse für den Dauereinsatz im Bereich Aluminium und Holz mit 1 kW Servomotoren 6,5 kW Hiteco Spindel und POP-UP Werkzeugmagazin

Für eine bessere Ansicht drehen Sie das Telefon auf Landscape.

Die Leistungsstärkste Portalfräse für den Dauereinsatz im Bereich Aluminium und Holz mit 1 kW Servomotoren 6,5 kW Hiteco Spindel und POP-UP Werkzeugmagazin

Für eine bessere Ansicht drehen Sie das Telefon auf Landscape.

Im Vergleich zur V-S Kraftübertragung über Getriebe, 750 W Servomotoren .

Das System kann mit einem linearen Werkzeugwechsler von 4-16 Positionen ausgestattet werden.

Spindelleistungen von 4,5 kW – 12 kW.

Für eine bessere Ansicht drehen Sie das Telefon auf Landscape.

Unsere Standard Maschine, der kostengünstige Einstieg in die CNC Automation, wahlweise mit Schritt- oder Servomotoren, automatischem Werkzeugwechsel 4-16 Positonen, Spindelleistungen von 4,5 kW – 12 kW

Für eine bessere Ansicht drehen Sie das Telefon auf Landscape.

Die V-DC ist eine moderne Flachbett-Schneideanlage. Sie ist für diverse Schneide-Anforderungen konzipiert, die automatisches Stanzen, Rillen und schneiden erfordern.

Für eine bessere Ansicht drehen Sie das Telefon auf Landscape.

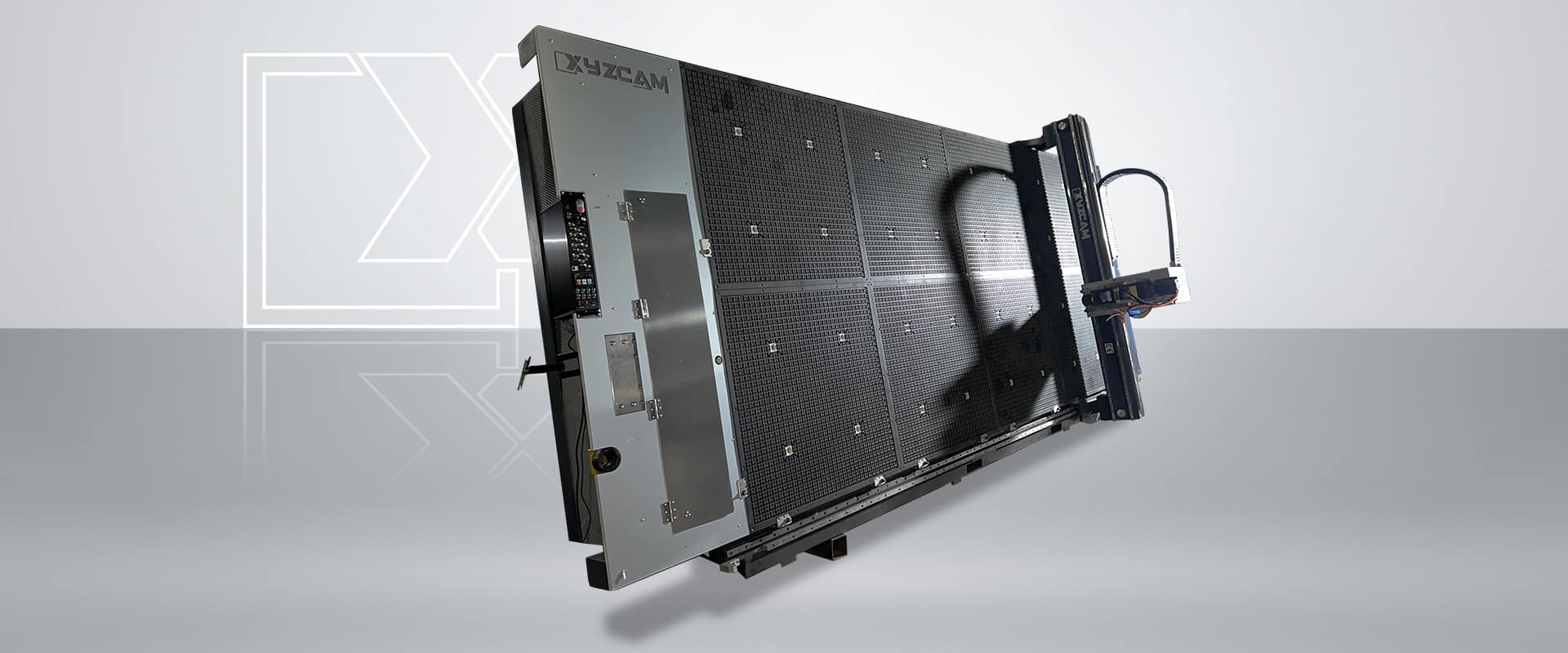

60 % Platzersparnis, Plattenbearbeitung vertikal, einfaches beladen, Fräsbearbeitung und Bearbeitung mit diversen Aggregaten, intelligenter Vakuumtisch, automatischer Werkzeugwechsel, Spindelleistung von 4,5-12 kW

Für eine bessere Ansicht drehen Sie das Telefon auf Landscape.

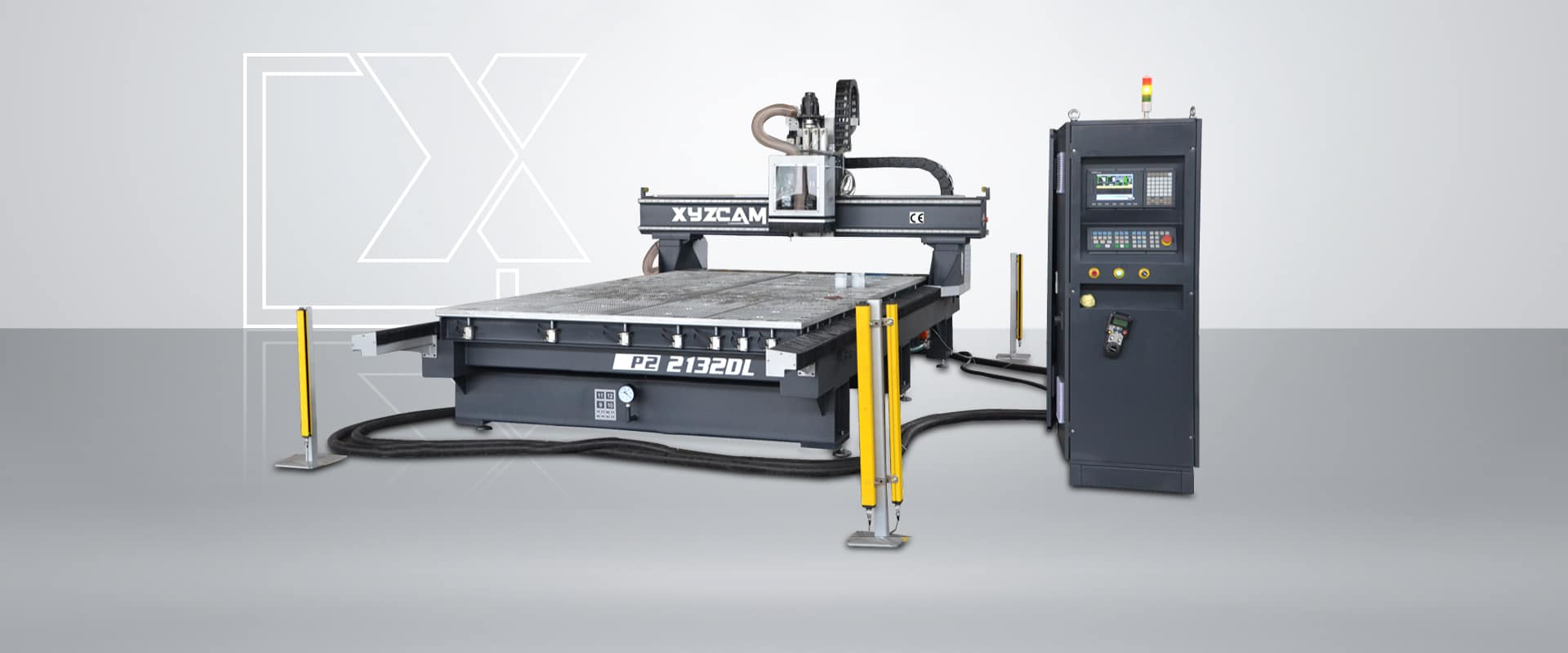

Die Profi Serie, mehr Gewicht, mehr Leistung, ausgestattet mit Yaskawa Servo Motoren, für den 3-Schicht Betrieb geeignet, Steuerung nach Kundenwunsch, wie Siemens, Beckhoff usw,

Für eine bessere Ansicht drehen Sie das Telefon auf Landscape.

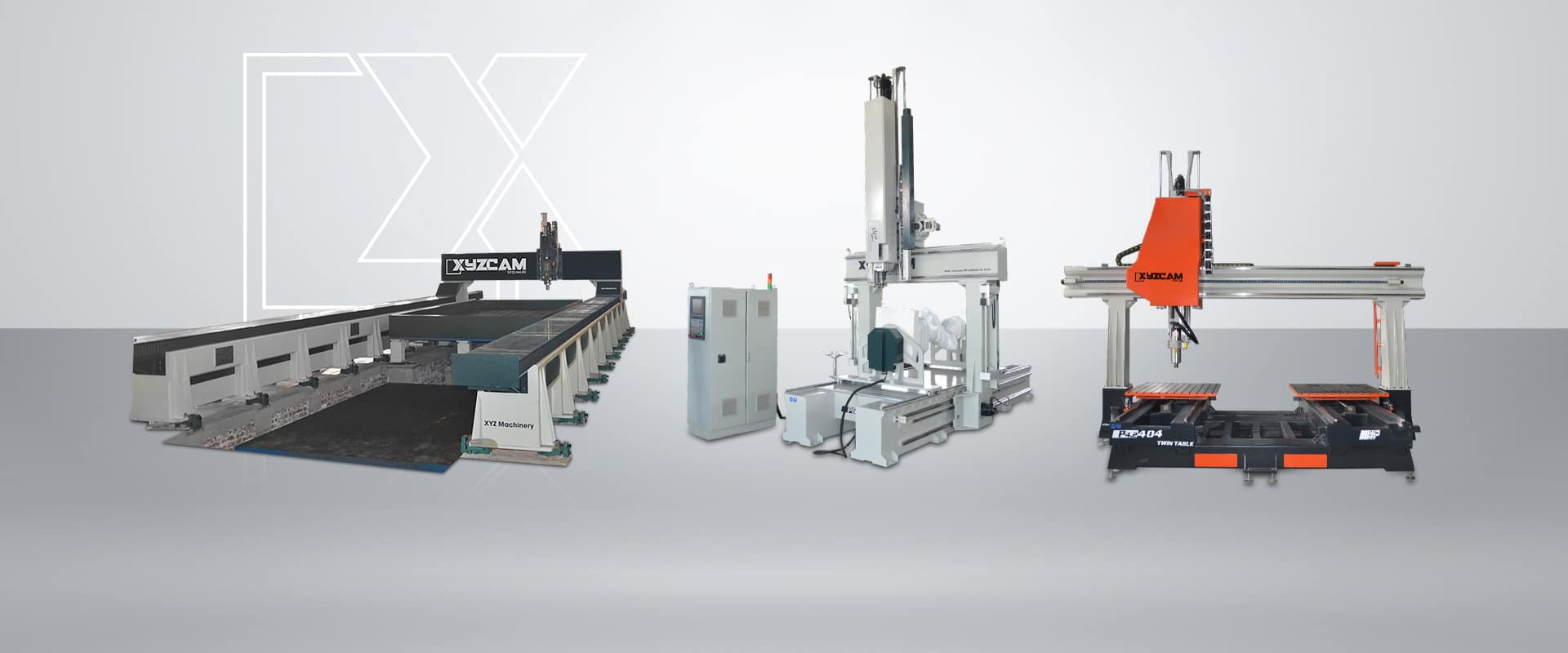

Maßgefertigte Werkzeugmaschinen, die für spezielle Anwendungen in der CNC-Frästechnik entwickelt werden. Diese Maschinen sind auf die individuellen Anforderungen eines bestimmten Projekts oder einer speziellen Produktionsaufgabe zugeschnitten.

Für eine bessere Ansicht drehen Sie das Telefon auf Landscape.

Bessere Ansicht durch drehen des Handys auf Landscape.

Die Leistungsstärkste Portalfräse für den Dauereinsatz im Bereich Aluminium und Holz mit 1 kW Servomotoren 6,5 kW Hiteco Spindel und POP-UP Werkzeugmagazin

Bessere Ansicht durch drehen des Handys auf Landscape.

Im Vergleich zur V-S Kraftübertragung über Getriebe, 750 W Servomotoren .

Das System kann mit einem linearen Werkzeugwechsler von 4-16 Positionen ausgestattet werden.

Spindelleistungen von 4,5 kW – 12 kW.

Bessere Ansicht durch drehen des Handys auf Landscape.

Unsere Standard Maschine, der kostengünstige Einstieg in die CNC Automation, wahlweise mit Schritt- oder Servomotoren, automatischem Werkzeugwechsel 4-16 Positonen, Spindelleistungen von 4,5 kW – 12 kW

Bessere Ansicht durch drehen des Handys auf Landscape.

Die V-DC ist eine moderne Flachbett-Schneideanlage. Sie ist für diverse Schneide-Anforderungen konzipiert, die automatisches Stanzen, Rillen und schneiden erfordern.

Bessere Ansicht durch drehen des Handys auf Landscape.

60 % Platzersparnis, Plattenbearbeitung vertikal, einfaches beladen, Fräsbearbeitung und Bearbeitung mit diversen Aggregaten, intelligenter Vakuumtisch, automatischer Werkzeugwechsel, Spindelleistung von 4,5-12 kW

Bessere Ansicht durch drehen des Handys auf Landscape.

Die Profi Serie, mehr Gewicht, mehr Leistung, ausgestattet mit Yaskawa Servo Motoren, für den 3-Schicht Betrieb geeignet, Steuerung nach Kundenwunsch, wie Siemens, Beckhoff usw,

Bessere Ansicht durch drehen des Handys auf Landscape.

Maßgefertigte Werkzeugmaschinen, die für spezielle Anwendungen in der CNC-Frästechnik entwickelt werden. Diese Maschinen sind auf die individuellen Anforderungen eines bestimmten Projekts oder einer speziellen Produktionsaufgabe zugeschnitten.

Unser Team hat mehr als 15 Jahre Erfahrung im CNC Maschinenbau. Wir sind spezialisiert auf die Entwicklung und Produktion von Portalfräsmaschinen & Lasermaschinen.

Erfahrungswerte aus der Produktion treffen auf Innovation und führen so zu höchster Effizienz unserer CNC Maschinen.

Dank unserer strategischen Partnerschaften mit Branchen-erfahrenen Unternehmen liefern wir unsere CNC Lösungen weltweit.

Bei einem kostenlosen Beratungsgespräch finden wir Ihre individuelle Lösung.