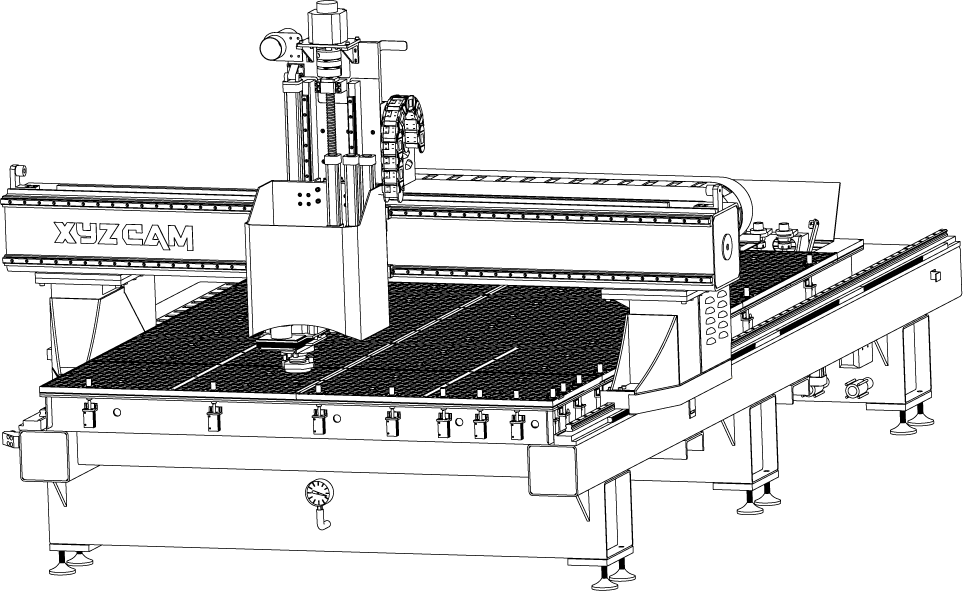

XYZCAM P1-Series - Heavy duty CNC portal milling machine with manual tool change

The three-axis CNC milling machine of the P1 series is the most flexible and reliable XYZ machine series that offers the highest cutting accuracy with fast movements.

Applicable materials:

- Polystyrene foams

- Wood products

- Solid wood

- Plastics

- Aluminum and composites

- Non-ferrous metals

Available models:

P1-1325, P1-1530, P1-2030, P1-2040

from 29.000 € (excl. VAT)

Functions

Properties & Specifications

Features | Specifications | |||||

Model | 408(1325) | 510(1530) | 710(2030) | 714(2040) | ||

Table Size | 1330x2540mm / 52″x100″ | 1590x3050mm / 62″x120″ | 2100x3050mm / 82″x120″ | 2100x4100mm / 82″x160″ | ||

X,Y Working Area | 1270x2540x203mm / 4´2〞x 8´4〞x 0.67’/ 50″x100″x8″ | 1524×3048 x203mm / 5´x 10´x 0.67’/ 60″x120″ x8″ | 2032×3048 x203mm / 6´8〞x 10´x 0.67’/ 80″x120″ x8″ | 2032×4064 x203mm / 6´8〞x 13´4〞x 0.67’ / 80″x160″ x8″ | ||

Z Stroke | 203mm/8’’ | |||||

Table Structure | Vacuum + T slot | |||||

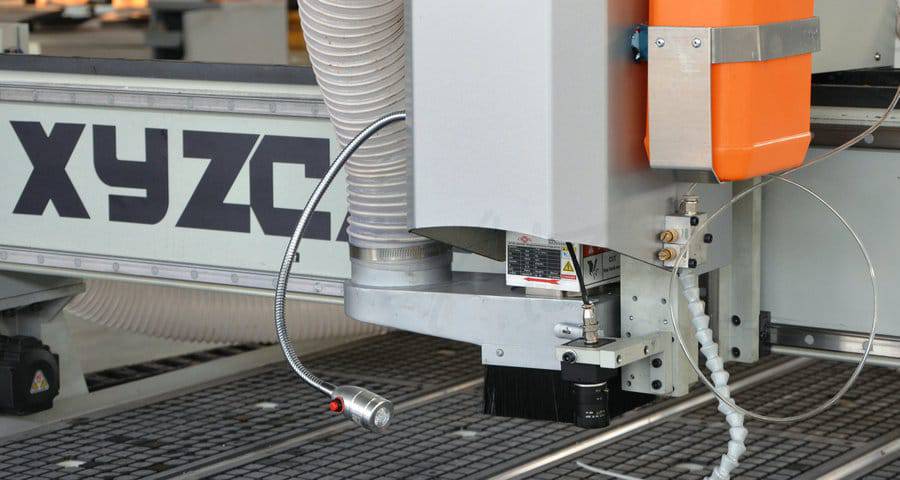

Transmission | Helical rack and pinion on X axis Y, ball screw on Z axis | |||||

Driving Mode | AC Servo / Hybrid servo / Stepper motor coupling gear reducer | |||||

Max Idle Speed | 60m/min (AC Servo) | 30m/min (Hybrid Servo) | 25m/min (Stepper) | |||

Max Working Speed | 42m/min (AC Servo) | 20m/min (Hybrid Servo) | 15m/min (Stepper) | |||

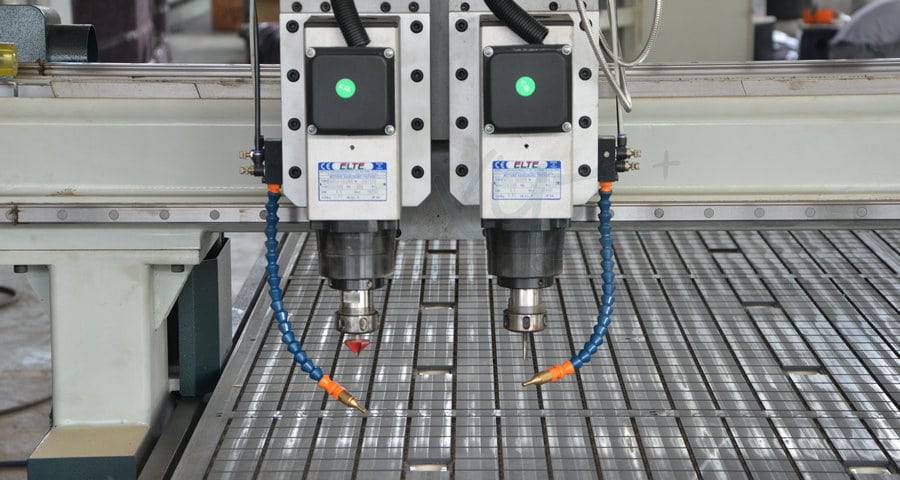

Spindle Motor | High Frequency Air Cooled, 3.0KW | High Frequency Air Cooled, 6.0KW | ||||

Working Mode | 18000r/min or 24000r/min | |||||

Working Voltage | AC380V | |||||

Command | G Code | |||||

Interface | USB, Network cable or Ethernet | |||||

Software | Artcam, Type3, Aspire, Fusion360,Cut2D | |||||