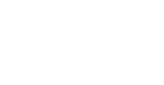

Available models: P7-505, P7-404, P7-606

Designed for excellent machining accuracy and edge finish, especially suitable for sign industries, free-painting, precise die mould…

Applicable materials:

- wood products

- solid wood

- plastics

- non-ferrous metals

- etc.

|

Features |

Specifications |

||

|

Model |

505 (1515) |

404 (1212) |

606 (1818) |

|

Table Size |

1590x1590mm/62″x62″ |

1220x1400mm/48″x55″ |

1890x 1890mm/144″x144″ |

|

X,Y Working Area |

1524x1524mm/5´x 5´’/ 60″x60″” |

1220x1220mm/4´x 4´/ 48″x48″ |

1830x1830mm/6´x 6´/ 72″x72″ |

|

Z Stroke |

914mm(36’’) |

||

|

Table Structure |

Cast Aluminum table with T slot (Vacuum for option) |

||

|

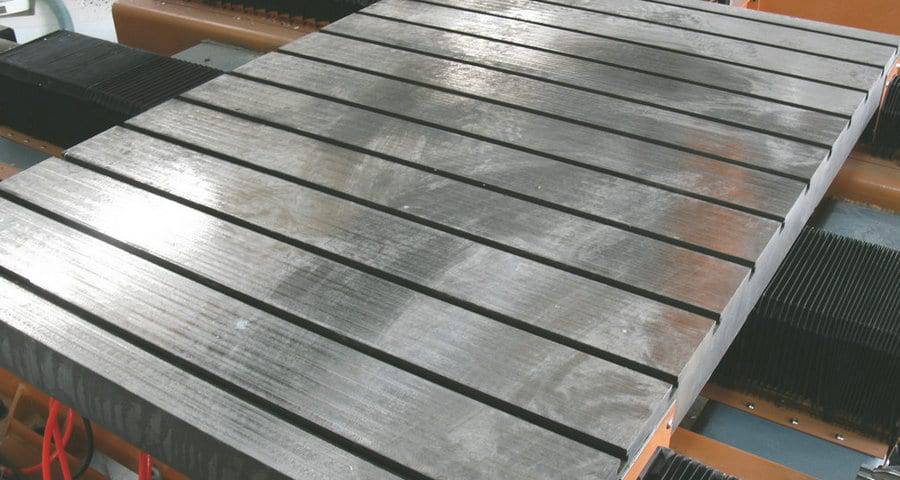

Transmission |

Ball screw on X, Y, Z axis (precision ground) |

||

|

Driving Mode |

Servo |

||

|

Max Idle Speed |

40m/min |

||

|

Max Working Speed |

20m/min |

||

|

Spindle Motor |

Water Cooled/ Air Cooled 10KW, 12.0KW |

||

|

Working Mode |

24000r/min |

||

|

Working Voltage |

AC380V |

||

|

Command |

G Code, DXF |

||

|

Interface |

PC |

||

|

Software |

MadCAM, Powermill and UG… |

||